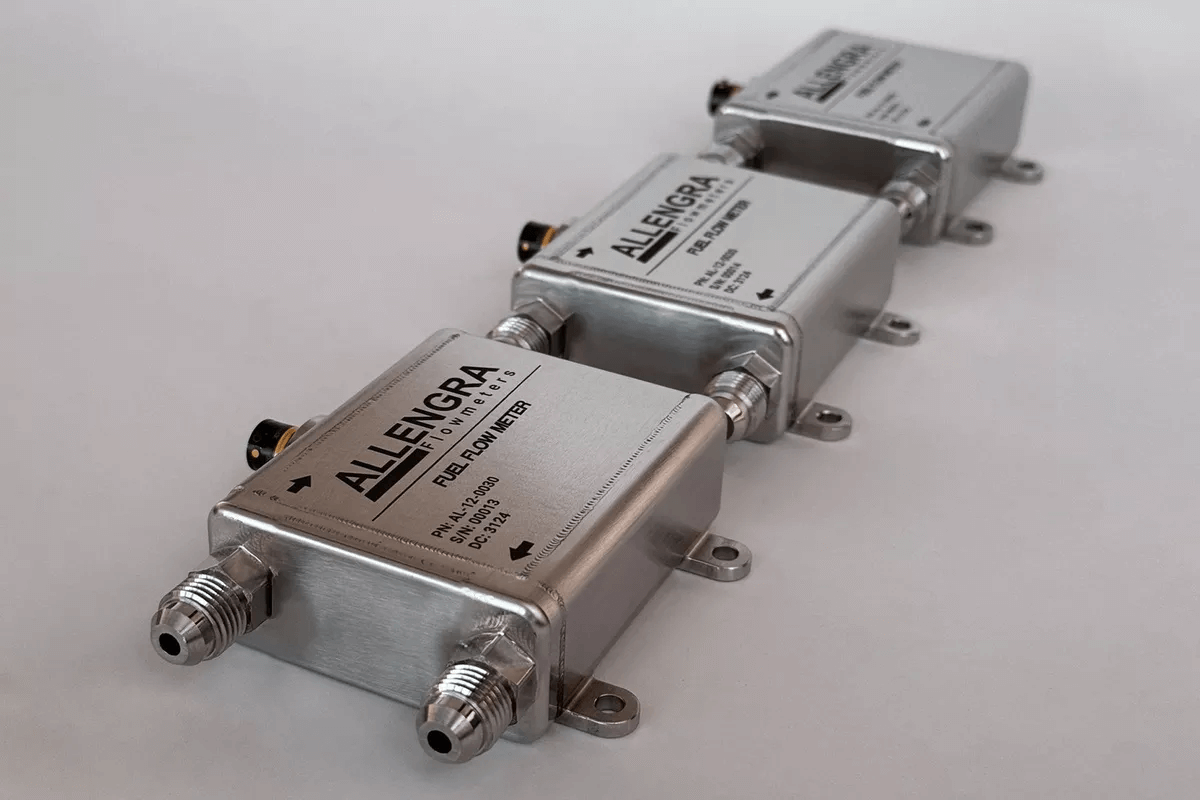

Since the introduction of the turbo-hybrid era in 2014, the fuel flow meter has evolved from a simple regulatory device into one of Formula 1's most critical technical components. As the pinnacle of motorsport prepares for its most dramatic regulation overhaul in over a decade, the technology governing engine fuel delivery is undergoing an equally profound transformation. From 2026, a revolutionary new flow meter from Allengra will replace the dual-meter system that has defined the current technical cycle, bringing with it unprecedented sophistication, security, and measurement capability.

This transition represents far more than a supplier change. It marks a fundamental shift in how the FIA will police the sport's most sensitive parameters, with implications that will reshape manufacturer strategies, fuel development priorities, and the technological arms race at the heart of Formula 1.

For years, Sentronics equipped every Formula 1 car with two separate fuel flow meters—one accessible to teams for real-time data monitoring, and a second encrypted unit exclusively accessible to the FIA. This dual-meter architecture was itself the product of controversy, introduced following the 2019 fuel flow meter disputes that exposed vulnerabilities in the existing regulatory framework.

However, as Formula 1 transitions to a radically different power unit architecture featuring a 50-50 split between internal combustion and electrical power, the limitations of the existing system became apparent. The FIA required a more advanced, multifunctional unit capable of consolidating two separate meters into one compact device while simultaneously enhancing security against potential manipulation.

Allengra, selected through a competitive tender process, rose to this challenge. According to Niels Junker, co-CEO of Allengra, the new design represents a fundamental reimagining of flow meter architecture: "One could say they are like two units in one. A major advantage is that the pipes have a different geometry, which makes it mechanically difficult to synchronise them perfectly at the same instant, even when using the same measurement frequency."

The new Allengra meter employs a multi-layered security architecture specifically engineered to prevent teams from circumventing regulatory limits—a concern that has haunted Formula 1 since the turbohybrid regulations began.

The system operates on three distinct security principles:

First-level protection: The two measurement pipes employ fundamentally different geometries, making mechanical synchronization extraordinarily difficult even before electronic safeguards come into play.

Second-level protection: Each pipe operates at its own distinct measurement frequency, further reinforced by anti-aliasing functions that prevent signal alignment. As Junker explains, teams cannot synchronize with their own flow meter's frequency without simultaneously replicating the encrypted FIA unit's frequency—a mathematical impossibility.

Third-level protection: The encrypted FIA meter operates at a frequency that remains completely inaccessible in real-time, accessible only through secure FIA channels. Even if a team theoretically synchronized with its own meter, it could never replicate the hidden unit's measurements.

The result, according to technical documentation, is a "multi-level security system designed to prevent any attempts to synchronise with or manipulate the recorded values."

Perhaps the most striking technical advancement in the Allengra system is its measurement speed. Operating between 4 and 6kHz, the new meter samples fuel flow data approximately 6,000 times per second—roughly three times faster than existing Sentronics technology.

This unprecedented sampling rate necessitated innovation in calibration methodology. The system cannot be validated using conventional Coriolis sensors (operating at 300Hz) commonly employed in factory testing environments. To address this, Allengra developed an in-house 20kHz ultrasonic reference sensor capable of validating the rapid measurements in real-time.

The measurement principle itself employs elegant physics. Within a flattened "U"-shaped chamber, fuel enters from one side while two opposing ultrasonic transducers exchange signals across the fuel column. Under static conditions, the signal transit time is predetermined. However, when fuel flows through the system, it acts like a current affecting signal propagation—accelerating the signal in the direction of flow and decelerating it in the opposite direction, precisely analogous to a boat traveling with or against river currents.

By measuring the differential transit times and knowing the transducer separation distance, the system calculates fluid velocity with exceptional precision. Combined with knowledge of the pipe's internal diameter, this yields volumetric flow rate. Crucially, the system then converts this to mass flow rate—the regulatory parameter expressed in kilograms per hour—accounting for variations in fuel density and temperature conditions.

From 2026, the new meter will fundamentally transform regulatory philosophy by shifting focus from mass flow limitations to energy flow monitoring.

The 2026 fuel flow mass limit drops to just over 70 kg/h, representing a significant reduction from the current era. However, the transformative change involves introducing an absolute energy flow ceiling of 3,000 MJ/h (megajoules per hour).

Before arriving at circuits, all fuel characteristics and energy values will be certified by an independent third party, ensuring standardization. The engine's homologated ECU will convert the mass flow measurement (kg/h) into fuel energy flow using certified energy density and lower heating values according to FIA-specified procedures.

This represents a strategic paradigm shift with profound implications. A manufacturer developing fuel with superior energy density can deliver the same required energy while flowing less mass—translating directly into weight savings and performance advantages.

Consider the regulatory formula below 10,500 rpm: EF (MJ/h) = 0.27 × N (engine speed in rpm) + 165. Different fuel formulations will generate different energy outputs at identical mass flows, creating a technology race among fuel suppliers that will fundamentally shape the 2026 competitive landscape.

The Allengra system has already undergone rigorous on-track validation through multiple 2025 tests. During the Abu Dhabi post-season test in late 2025, the new meter was installed in Mercedes, McLaren, Williams, and Sauber machines, operating in parallel with existing Sentronics equipment to ensure seamless transition. Data from the Allengra meter transmitted through secure FIA channels, completely segregated from team and Sentronics systems.

The Allengra fuel flow meter represents the pinnacle of regulatory technology—a device engineered not merely to measure, but to prevent circumvention through sophisticated multi-layered security while simultaneously opening new frontiers in fuel technology development. As Formula 1 enters its next regulatory era, this unassuming onboard component will prove decisive in determining which manufacturers unlock competitive advantage through innovation in energy density, efficiency, and thermal management.

The race for 2026 supremacy will be won not just on circuit, but in laboratories where fuel scientists pursue marginal gains in energy content per kilogram. The Allengra meter ensures every advantage is transparently measured, meticulously regulated, and completely secure.

Source: Motorsport.com

He’s a software engineer with a deep passion for Formula 1 and motorsport. He co-founded Formula Live Pulse to make live telemetry and race insights accessible, visual, and easy to follow.

Want to add a comment? Download our app to join the conversation!

Comments

No comments yet

Be the first to share your thoughts!